Services

Comprehensive solutions tailored to meet your engineering needs

Remedial

Concrete repair can be a costly, getting it right the first time is important. Product selection is where Ironstone Civil and our supply partners excel

Specialised grouting

Structural relining options are increasing being considered. Ironstone Civil provides structural relining of tunnels and culverts using cementitious or chemical grouts.

Construction

Water leakage can cause significant damage to structures and reduce their economic life. We offer range of solutions available to stop water leaks in large buildings, large infrastructure and tunnels.

Remedial

Concrete Repair

Well designed and properly constructed reinforced concrete structures can have long service lives. But they are not immune to damage because of, deterioration over time, foundation movement, chemical or environmental damage, and in some rare occasions structural damage (e.g., due to earthquakes). The damage is often seen as cracking of the concrete, or corrosion of the reinforcing steel which then causes concrete spalling. Concrete maintenance and early repair of damage are essential to ensure a structure’s long term structural integrity.

Concrete repairs are, in general, straight forward but complications due to difficult access, heat, cold, moisture, water seepage, can often occur. Also, concrete repair can be a costly so getting it right the first time is important. Sometimes the repairs are ineffective, or failure and this is usually caused by incorrect material selection and application

Product selection is key, and this is where Ironstone Civil and our supply partners experience is essential. Nothing is more important than having experienced applicators who understand the importance of working to strict quality procedures.

Structural relining of tunnels and culverts

Many of today’s culvert and tunnel infrastructure is in need of maintenance or replacement.Replacement is often impractical because it can cause unacceptable downtime or is cost prohibitive, so structural relining options are increasing being considered.

Ironstone Civil provides structural relining of tunnels and culverts using cementitious or chemical grouts. For larger diameter culverts of 1.8m diameter and above we use Geopolymer reinforced grouts that are centrifugally sprayed onto the culvert to create a new culvert within a culvert. Once the Geopolymer sets the new culvert structurally replaces the old host culvert. The reinforced grout is typically applied at a thickness of around 50mm* thus hydraulic capacity loss is minimised compared with some other solutions.

* Design thickness will depend on many variables and engineering designs are recommended for all structural replacement.

Water stopping and water proofing

Water leakage can cause significant damage to structures and reduce their economic life. In addition, water leakage can damage stock or seriously reduce the utility of a structure.

Where water is expected to be present structures are usually designed and constructed to have watertight integrity, that is, to prevent water egress from containment structures or water ingress into structures.

Despite these precautions during construction, unplanned water ingress and egress can still occur. Changing environmental conditions, faulty or inadequate design or construction, damage or simply deterioration of the structure over time, can all be contributing factors. In the instance where an asset is ageing, certain materials may have exceeded their lifespans. Stopping water ingress can be very challenging because it is often impossible to know with precision what you are dealing with. This is where know how and experience come together solve water stopping problems.

Ironstone Civil through our supplier partners have a range of solutions available to stop water leaks in large buildings, large infrastructure and tunnels. Whether it be large water ingress or minor leaks Ironstone Civil have the experience to solve the problem.

Concrete crack injection

Joint sealant repairs

HDPE liner repair

Specialised grouting

Void and anulus fill

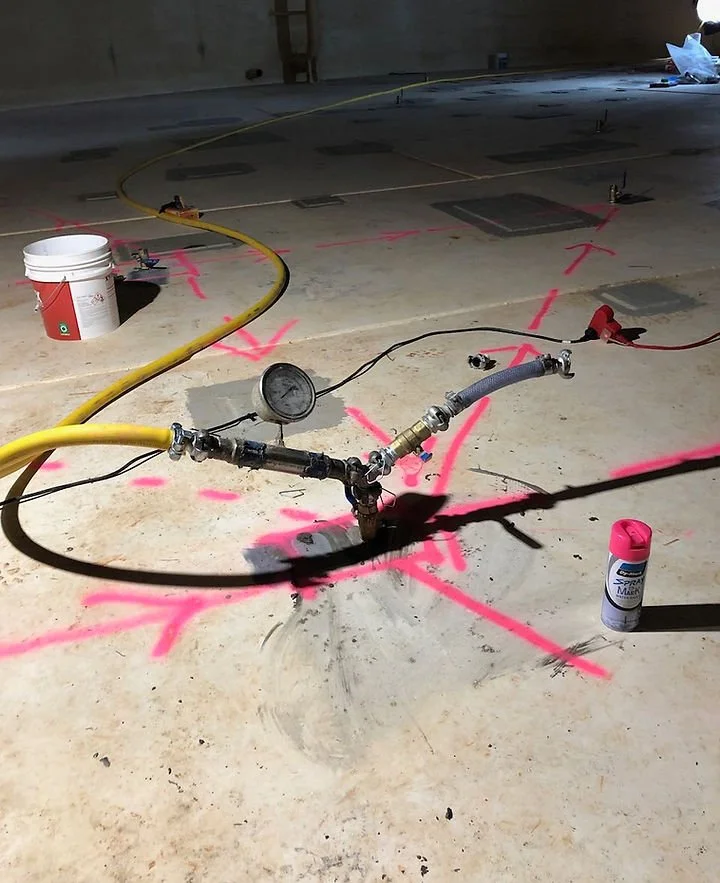

Voiding under structures is often caused by settlement or washing away of foundation soils. This voiding can compromise the structural integrity of the structure, particularly if the structure was designed to rely on the soil for structural support. Ironstone Civil have experience of filling voids under buildings, warehouse slabs, behind retaining walls and under storage tanks.

Another application is the abandonment of infrastructure, i.e., where removal of the asset is uneconomical, but the asset owner wants to ensure that the asset will be permanently filled and remain inert far into the future. The sorts of assets abandoned are water, gas, oil and sewerage pipes, or tunnels and culverts.

A specialised application is the filling of the annulus created when a new pipe is inserted into a redundant host pipe. There are many types of grouts available depending on the application. Sometimes a rapid set time is required or high flowability or a higher strength product.

Ironstone Civils’ team have carried numerous void fill and abandonments in the mining, water, road and rail infrastructure sectors, throughout Australia

Permeation grouting

Permeation grouting can be an effective technique to strengthen sandy soils by filling the void spaces between the sand grains and aggregating the sand. Essentially a highly flowable grout comprised of fine cement and water is injected under low pressure into the soil. The flowable grout fills voids and as it sets it forms an aggregated block of soil.

The block that is created can be used to support buildings and structures or to enable temporary excavations adjacent to these structures. For any substantial works carrying out an engineered design is essential. There are several cement types that can be used varying from standard cements to ultra fine ground cements. Matching the cement to the soil type is an important consideration.

Successful permeation grouting relies heavily on the experience and expertise of the permeation technicians and correct material selection.

Pipe abandonment

Contact Grouting

Construction

Bridge deck waterproofing

HDPE Liner installation

Lightweight Flowable Fill

Lightweight flowable fill is an innovative solution designed for a variety of construction applications. This versatile material combines the benefits of low density with high flowability, making it ideal for backfilling, void filling, and slope stabilization. Its unique properties allow for easy placement and quick curing, reducing labor and project timelines. Additionally, lightweight flowable fill helps minimize the risk of settlement and offers excellent load-bearing capabilities, ensuring a stable foundation for your projects. Environmentally friendly and cost-effective, it stands out as a reliable choice for modern engineering challenges.

Ironstone Civil’s lightweight Flowable Fill, LF-Fill is a low density polymer modified grout. LF-Fill is produced from a GP cement and water slurry, mixed with a prepared foam surfactant. LF-Fill is mixed on site using a specially formulated base slurry of GP cement, potable water and foam surfactant. The batching process requires special grout pumps and a surfactant foam generator and slurry/foam mixer.

The base slurry can be supplied from a pre-mixed concrete batch plant, or be produced on site using volumetric mixers or, for small quantities, mixed from 20kg GP cement bags in a small mixer / pump.