Our specialty products

Ironstone Civil specialises in high-quality, durable products designed to meet demanding needs. Ensuring superior performance and reliability for every project.

LF-FILL Lightweight Flowable Fill

Ironstone Civil’s lightweight Flowable Fill, LF-Fill is a low density polymer modified grout. LF-Fill is produced from a GP cement and water slurry, mixed with a prepared foam surfactant. A surfactant concentrate is introduced into foam generator and mixed with water to produce a foam with a high proportion of stable air voids or “small bubbles”. A pump is used to used to mix the foam with the slurry. The resultant LF-Fill is a highly flowable lightweight material that has proven to be extremely useful and versatile in many civil engineering applications.

Once produced LF-Fill behaves like other cement based products and has a measurable initial set time, final set time, and compressive strength which gains over time.

LF-Fill is mixed on site using a specially formulated base slurry of GP cement, potable water and foam surfactant. The batching process requires special grout pumps and a surfactant foam generator and slurry/foam mixer. The base slurry can be supplied from a pre-mixed concrete batch plant, or be produced on site using volumetric mixers or, for small quantities, mixed from 20kg GP cement bags in a small mixer / pump. The production process requires LF-Fill to be produced “on demand” meaning that the LF-Fill must be installed directly after it is produced.

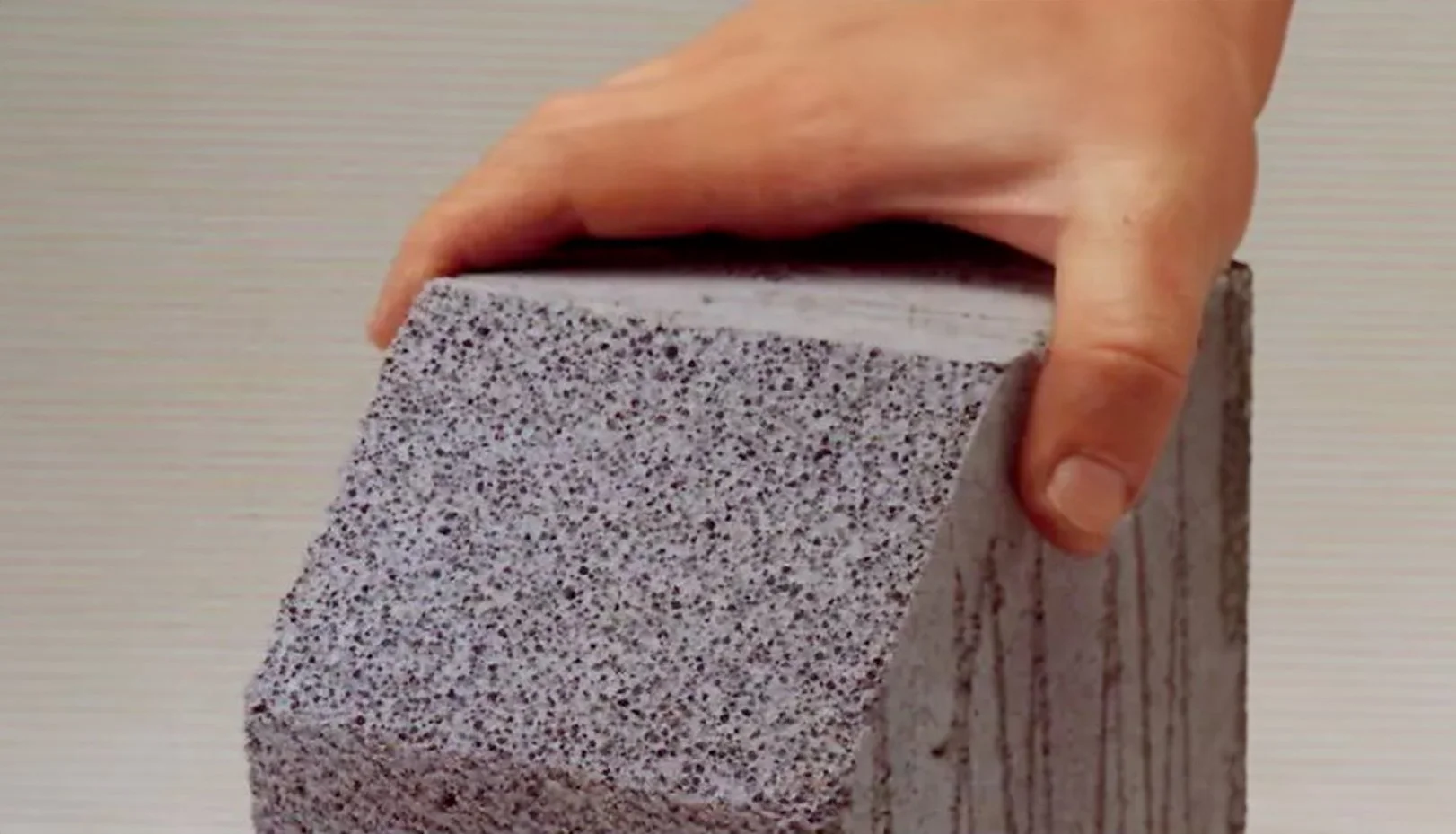

Geocast Geopolymer concrete

An innovative and sustainable construction material that serves as an environmentally friendly alternative to traditional Portland cement. Unlike conventional concrete, which generates high carbon emissions during its production, Geocast Geopolymer concrete utilises industrial by products like fly ash, slag, or rice husk ash, which are rich in aluminosilicate materials. These waste materials are activated using alkaline solutions to form a binder, resulting in a concrete mixture with excellent strength and durability. By using waste materials, this concrete not only helps reduce landfill waste but also significantly cuts down the carbon footprint associated with traditional cement production.

In addition to its environmental benefits, Geocast Geopolymer concrete offers superior performance compared to conventional concrete. It exhibits enhanced resistance to heat, fire, and chemical attacks, making it ideal for use in harsh environments such as industrial facilities or structures exposed to high temperatures. Moreover, the unique composition of Geocast allows it to achieve higher compressive strength at a faster curing rate, which can lead to faster construction times. As the demand for more sustainable construction practices increases, Geocast Geopolymer concrete represents a promising solution that combines eco-consciousness with high performance, contributing to a more sustainable future for the construction industry.